Piston Engine Parts: Your Comprehensive Guide to Quality and Performance

When it comes to the world of diesel engine components, piston engine parts play a critical role in ensuring optimal performance and longevity. In this article, we'll delve deeply into the functionalities, characteristics, and importance of these components, helping you better understand how they contribute to your engine's efficiency.

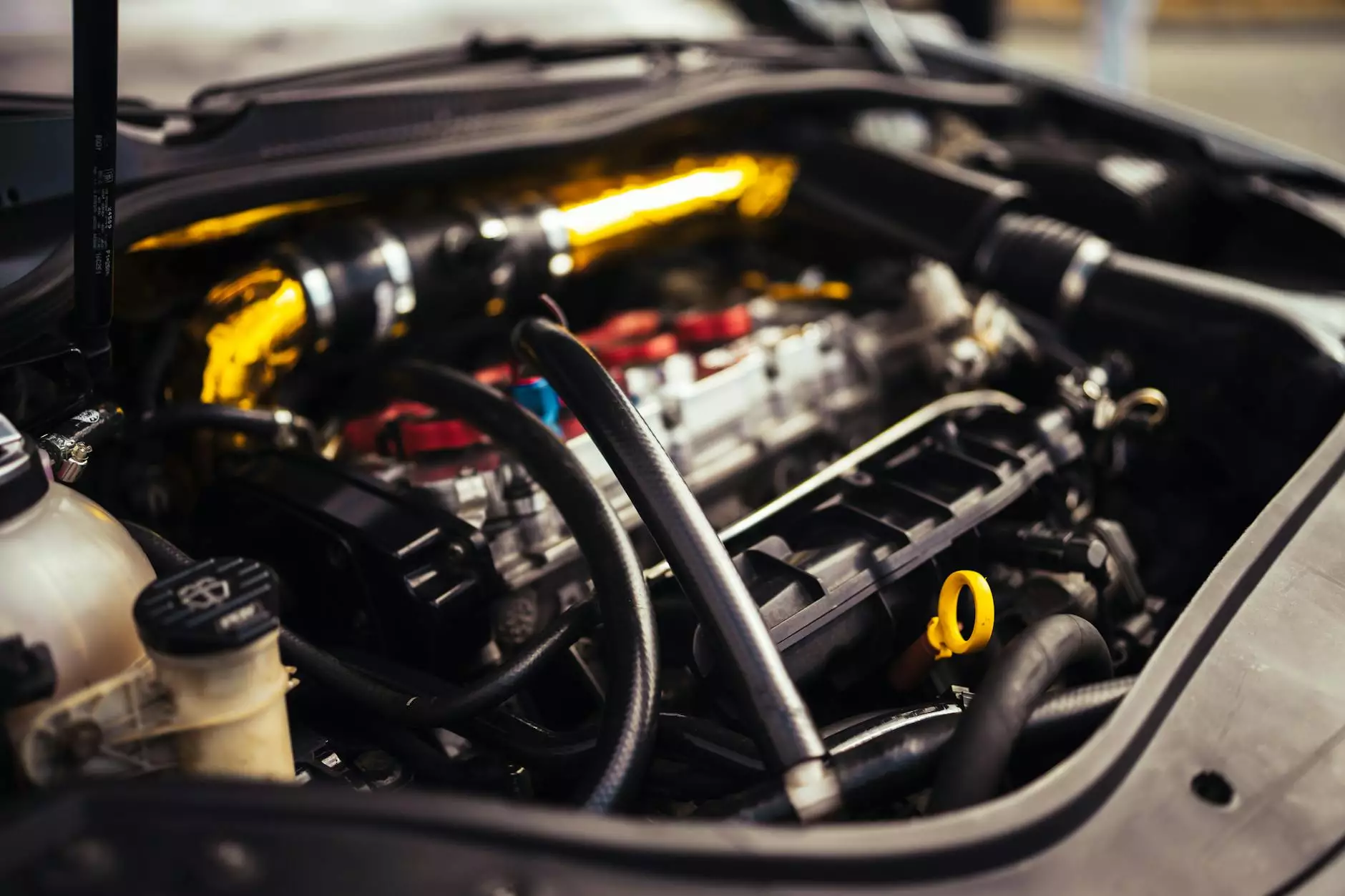

Understanding Piston Engine Parts

Piston engine parts are essential components of internal combustion engines, particularly in diesel engines. At the heart of the engine, the pistons translate the energy from combustion into mechanical work. This section will explore various piston engine parts, their functions, and their significance in your engine's operation.

The Role of Pistons in Diesel Engines

The piston is arguably the most crucial of all piston engine parts. It moves up and down within the cylinder, compressing the air-fuel mixture and converting the chemical energy from the fuel into mechanical energy. Here are a few key points about pistons:

- Compression Ratio: The shape and material of the piston can significantly affect the compression ratio of the engine.

- Cooling: Pistons must also dissipate heat effectively to prevent overheating.

- Durability: High-quality pistons are crucial for long-lasting engine performance.

Components of the Piston Assembly

The piston assembly includes several other piston engine parts. Each component plays a unique role in the assembly, contributing to its overall functionality. Some major parts include:

- Piston Rings: These are crucial for sealing the combustion chamber and controlling oil consumption.

- Piston Pin: This connects the piston to the connecting rod and allows for smooth rotation.

- Cylinder Liner: The serviceable sleeve where the piston moves up and down.

Importance of High-Quality Piston Engine Parts

Choosing the right piston engine parts is imperative for your engine's performance and efficiency. Poor quality components can lead to engine failure, increased maintenance costs, and reduced fuel efficiency. Here's why you should prioritize quality:

- Performance: Superior materials and manufacturing processes ensure better performance under high stress.

- Reliability: Quality parts tend to last longer, minimizing the risk of breakdowns.

- Cost Efficiency: Investing in quality parts often translates to long-term savings in maintenance and repairs.

Common Issues with Piston Engine Parts

Even the best piston engine parts can experience wear and tear over time. Understanding these issues can help you maintain your engine better:

Piston Ring Wear

Over time, piston rings can become worn due to friction and heat. Symptoms include increased oil consumption and loss of power. Regular checks of the piston rings can help prevent major repairs.

Piston Damage

Pistons can be subject to several types of damage including scuffing, cracking, and scoring. These issues can often arise from inadequate lubrication or the use of low-quality fuel.

Cylinder Scoring

While connected to the piston, the cylinder can also suffer from scoring that can lead to loss of compression. This is often caused by dirt or debris that has entered the engine.

How to Choose Quality Piston Engine Parts

Selecting quality parts can be daunting. Here are practical tips for choosing piston engine parts:

1. Research Suppliers

Look for spare parts suppliers who specialize in genuine or high-quality aftermarket components. Reading reviews and checking certifications can provide insight into their reliability.

2. Compare Specifications

Ensure that the specifications (like size, weight, and material) of the piston parts match or exceed OEM standards. This ensures compatibility and performance.

3. Evaluate Warranty Options

A good warranty can be an indicator of quality. Reputable suppliers often back their products with a warranty that assures performance and durability.

The Future of Piston Engine Parts

The evolution of diesel engines has brought about new technologies that impact piston engine parts. Here’s a look at some trends that are shaping the future:

1. Advanced Materials

New materials like forged aluminum and specialized alloys are improving the strength-to-weight ratio of pistons, enhancing performance while reducing weight.

2. Eco-Friendly Innovations

With a growing focus on reducing emissions, manufacturers are developing piston engine parts that more efficiently burn fuel and minimize waste.

3. Smart Technology

Smart sensors integrated into piston assemblies can provide real-time data to diagnose potential issues before they become serious problems.

Conclusion

Understanding piston engine parts and their significance in your diesel engine can greatly affect its performance and lifespan. Whether you're an engine enthusiast or a professional mechanic, knowing how to choose and maintain these parts can lead to enhanced efficiency and reliability.

Investing in high-quality piston engine parts from reputable spare parts suppliers like client-diesel.com ensures that your engine operates at peak performance, saving you time and money in the long run. Always remember: quality matters.